ASSIGNMENT 3 - REFLECTION [20%] - 13TH OF JUNE

QUESTION: THROUGH CONTRAST AND COMPARISON. COMPARING AND CONTRASTING ELEMENTS OF YOUR WORK AS IT DEVELOPED OVER THE SEMESTER WITH PREVIOUS EXAMPLES OF YOUR OWN WORK OR THE WORK OF YOUR CLASSMATES.

Currently in my third year i am studying 'BEIL0014 Digital Making'. I have chosen this unit to grow my confidence with dealing with different aspects within the construction field. The discipline I am currently studying is 'Construction Management and Property Development'. This involves managing the construction process from inception, design, construction and final completion. As part of my construction course I am required to select one BEIL subject, with the purpose to broaden my knowledge. Digital making has enabled me to appreciate the use of aluminium, and understand its complex nature and its ability to be manipulated to the need users desire. This can also assist me in the early design involvement with architects and designers.

DIGITAL MAKING: IMPACT ON MY CAREER

DIGITAL MAKING: IMPACT ON MY CAREER

Prior to this course, I never understood the significance aluminium has had on modern cities and towns. I now know that Aluminium has the ability to manipulate its form and create complex shapes. It is used in the construction industry today as it is functional and environmentally friendly. I am more aware of my surroundings and can observe that the glass faces of office skyscrapers are supported by lightweight and sturdy Aluminium frames, so do sport facilities, stadiums, entertainment, trade and exhibition centers, which has reinforced for me the influence aluminium has within the construction industry.

I realized that aluminium is widely used in the construction industry. This is due to its design service life of 80 years and ability to withstand any climatic condition and does not loose its properties in temperatures ranging - 80 degrees celsius - + 300 degrees celsius. This BEIL subject, has allowed me to further understand how aluminium can be used as a fire rated element as it has the ability to slow down the temperature. Another thing advantageous about aluminium is its weight which is two-thirds of the weight of steel. Thus digital making has significantly enhanced my knowledge on the properties aluminium holds and its importance within the construction industry.

I realized that aluminium is widely used in the construction industry. This is due to its design service life of 80 years and ability to withstand any climatic condition and does not loose its properties in temperatures ranging - 80 degrees celsius - + 300 degrees celsius. This BEIL subject, has allowed me to further understand how aluminium can be used as a fire rated element as it has the ability to slow down the temperature. Another thing advantageous about aluminium is its weight which is two-thirds of the weight of steel. Thus digital making has significantly enhanced my knowledge on the properties aluminium holds and its importance within the construction industry.

I currently work at a company called MJH Multi who specialise in multi residential building. The use of aluminium is heavily used within our projects. For example working on construction sites has allowed me to see aluminium roofs, domes, wall panels, door (similarly to image shown below) and window frames being constructed/installed daily. I am more confident in regards to speaking to trades and sending purchase orders as I have a greater understanding of the different properties aluminium withholds.

Here are some products we are currently using at MJH Multi:

|

| Aluminium window frames used at MJH Multi |

|

| Aluminium handrailing used at MJH Multi |

The images below illustrate the use of Aluminium and how it can be manipulated to create smooth curves and sharp points.

Throughout the course I was required to create five different models using aluminium. I created the below:

THE BOWL

THE TORUS

THE TRAY

THE BLISTER

THE FUEL TANK

The model I struggled with the most was the torus, as opposed to the bowl and the blister which I felt was less complex.

The first model I created was the bowl, which I was quite overwhelmed with the whole process, as it was my first task to complete. The tutors explained their different tasks very thoroughly which allowed me to understand the sequence of each step and successfully accomplish the task of creating the bowl. The purpose of this task is to understand how to transform a simple piece of sheet into complex shapes by shrinking and stretching the material. I learnt that shrinking and stretching the material will significantly change the overall area of the material. For this specific task I focused on shrinking the material to achieve a round circumference, unlike the torus which required me to stretch the aluminium to create a reverse curve. To shrink the metal I used a nylon mallet and began to hammer the inside than out. It took me a while to get comfortable with how to utilize the hammer, as I was unsure on how to hold it, however I did ask Daniel who explained that I needed to grip to bottom of the mallet and not the top.

Strengths Weaknesses

- Tenacity to learn - Rushing my work

- Ability to work as a team - Inability to create

- Persistence - Knowledge of the programs

(Fusion 360 & Illustrator)

Similarly the same method I used for the bowl was also used when creating the torus. I needed to shrink the inside of the aluminium and stretched the outer edges. From the bowl to the torus I developed different hammering methods which I utilised when making the tray and the blister. Figure 1.1 outlines the difference of methods used to achieve the bowl and the torus.

Strengths Weaknesses

- Tenacity to learn - Rushing my work

- Ability to work as a team - Inability to create

- Persistence - Knowledge of the programs

(Fusion 360 & Illustrator)

Similarly the same method I used for the bowl was also used when creating the torus. I needed to shrink the inside of the aluminium and stretched the outer edges. From the bowl to the torus I developed different hammering methods which I utilised when making the tray and the blister. Figure 1.1 outlines the difference of methods used to achieve the bowl and the torus.

As mentioned above the key difference between the bowl and the torus is the bowl used the method of shrinking the aluminium to reduce the surface area and create a round circumference, while the torus required me to stretch the aluminium to achieve the concavity. I also learnt when making the torus, is it completely different to the bowl, as the curves go in opposite direction.

Following on I felt more confident with the result of my bowl than the torus. I struggled forming the torus once I noticed my sheet began to form tiny tucks which couldn't be hammered out, due to me rushing my work. I decided to have another go using my second aluminium strip and trace two-lines creating a 70mm centre to help indicate where I should stump allowing for a better finish. I also took my time and aimed to remove any bumps using the replenishing hammer. However it still didn't turn out how I would've liked it to as there were many bumps in the centre of the aluminium sheet. Below figure shows my first aluminium sheet which I failed to rectify as a result had to start over.

Overall the key element that I developed from creating the bowl to the torus was to take my time on each step and be patient with the process.

In addition the techniques I learnt when creating the bowl I utilised when making the tray and blister. The same hammering methods were used throughout the every project. I developed a new skill when creating the tray which was making the plywood template to act as a mould for my tray. Also I had to partner up with someone and work towards matching both parts together, which allowed me to enhance my team work skills.

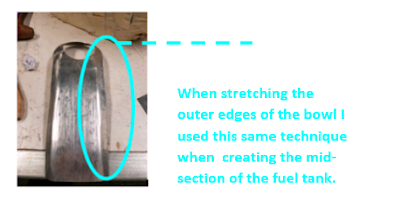

Finally my last task was to create a fuel tank. For me to achieve this I had to utilise the skills I gained in previous projects and replicate the fuel tank as closely as possible to the existing fuel tank model, however I mostly used the techniques I learnt when making the bowl. Refer to below table which illustrates the techniques I learnt when making the bowl and replicated it when making the fuel tank.

Skills I learnt:

- Hammer Forming

- Time Management

- How to use illustrator

- How to use the laser cutting machine (Fusion 360)

- How to use the sanding machine

- Interpersonal Skills

- Hammer Forming

- Time Management

- How to use illustrator

- How to use the laser cutting machine (Fusion 360)

- How to use the sanding machine

- Interpersonal Skills

In conclusion it is clearly evident that Digital making has allowed me to further develop as an individual and enhance my existing skills. I am able to effectively utilize everything I have learnt in this course and apply it to my current work, as I now have a greater understanding of the properties aluminium holds. Furthermore this course has allowed me to enhance my strengths and work on my weaknesses. Looking back I would've completed tasks differently and more efficiently, such as drawing more diagrams to understand the process visually. Overall I thoroughly enjoyed this course and it has definitely broadened my knowledge.

Comments

Post a Comment